Overview

BOREAS® dry cooling systems are designed for facilities operating with lower dry bulb temperatures and/or higher outbound process fluid temperatures. BOREAS dry coolers circulate process water through bundles of copper tubing and large fans pull outside air across the fins to cool that process water. These dry cooling systems also maximize energy efficiency with Smart Programming that cycles fans on and off in stages as cooling demands change.

NIMBUS® provides BOREAS dry cooling systems in a wide variety of configurations to accommodate the spatial and cooling requirements of nearly any facility. All BOREAS systems can be upgraded to VIRGA® adiabatic systems if needs or local legal requirements change.

BOREAS systems deliver years of efficient cooling while minimizing the risk of Legionnaires' disease, conserving water, and eliminating the costly maintenance programs associated with traditional evaporative coolers.

Features & Benefits

- Fans with Smart Programming cycle on and off in stages to optimize energy consumption

- EC or AC Fan Motors (with or without VFD) minimize energy consumption (BOREAS H-Series only available with EC)

- Stainless Steel Frame ensures years of operation compared to traditional dry coolers

- Easy Access Lift Points are bolted to the internal structure of every fan section for quick, simple, and safe lifting and positioning

- UL/UL-C Industrial Control Panels custom-built by NIMBUS offer direct 460V, 208V, or 575V applications as standard with fully contained PLC or digital controls

- Wide Range of Heat Rejection from 5 tons to 540 tons per unit

- Minimal Footprint requires less space than traditional dry coolers

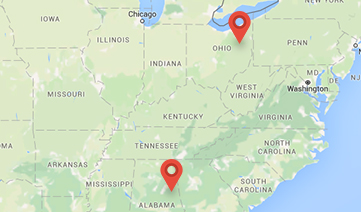

All BOREAS systems are designed, engineered, tested, and built by NIMBUS Advanced Process Cooling in the USA.

All BOREAS systems are designed, engineered, tested, and built by NIMBUS Advanced Process Cooling in the USA.

Applications

Commercial and Institutional

- Schools & Universities

- Hospitals/Health Care

- Government & Military

- Airports/Transportation Hubs

- High Rise Towers

- Shopping Centers/Retail

- Restaurants

- Correctional Facilities

- Casinos

INDUSTRIAL FACILITIES

- HVACR

- Data Farms

- Food Processing

- Wineries & Distilleries

- Grow Facilities

- Automotive Manufacturing

- Chemical Processing

- Thermoplastics

- And Others

Configurations

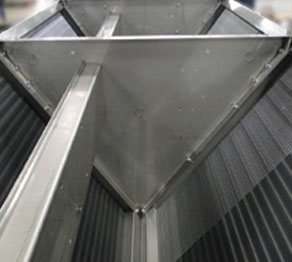

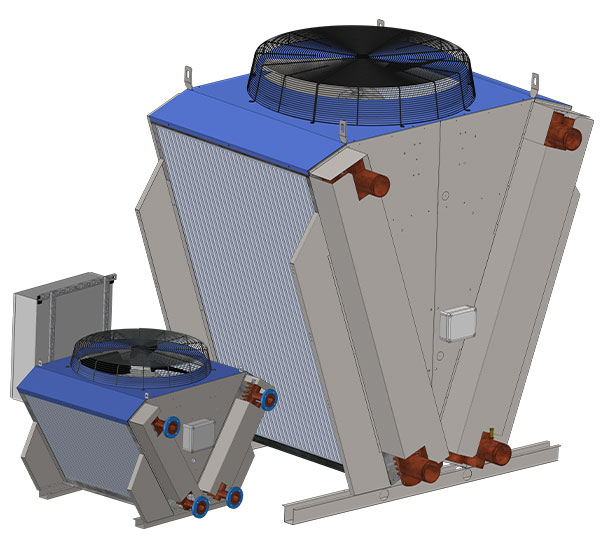

BOREAS® V-Series™ for traditional cooling needs, features 32.5 inch, 70 inch fins or 90 inch fins.

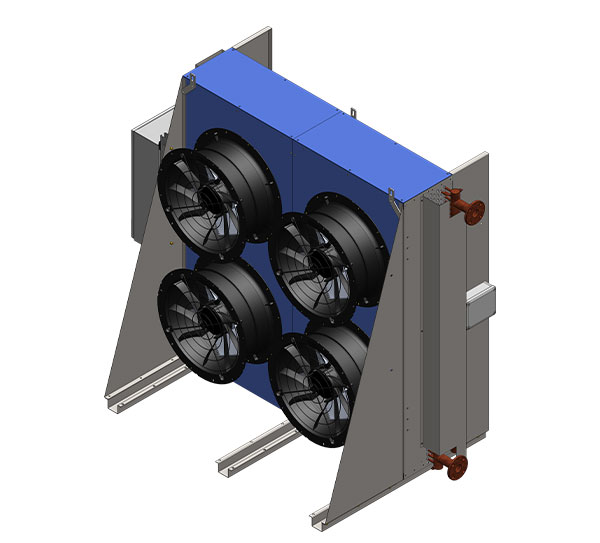

BOREAS® H-Series™ for limited-height environments, features horizontal airflow design and 72.5 inch fins.

Or contact NIMBUS today at 844.NIMBUS.3 to learn which type of cooling solution is best suited for your operational requirements.

Components

Controls

All BOREAS cooling systems feature UL/UL-C Industrial Control Panels custom-built by NIMBUS (UL-Certified). Panels are installed either directly on the cooling system or remotely. Controls installed directly on the cooling system are fully contained, requiring only the primary power connection on site. NIMBUS’ cooling systems feature Type 3R-rated enclosures as standard, with Type 4 and Type 4X available as options.

BOREAS units outfitted with EC (Electronically Commutated) fans come standard with PLC controllers. Units outfitted with AC (NEMA) fans include digital controls as standard with PLC controls and VFD, or no controls available as options. Standard EC fan packages and AC fan packages upgraded with VFD and PLC controls provide fan speed modulation, while standard AC fan packages with digital controls feature “on/off” fan staging.

All NIMBUS cooling systems arrive at the installation site pre-programmed to the customer’s specifications with the leaving fluid temperature sensors installed and wired. Users can adjust the set point to the desired leaving fluid temperature.